#!/usr/bin/env python

# coding: utf-8

#

# *This notebook contains course material from [CBE20255](https://jckantor.github.io/CBE20255)

# by Jeffrey Kantor (jeff at nd.edu); the content is available [on Github](https://github.com/jckantor/CBE20255.git).

# The text is released under the [CC-BY-NC-ND-4.0 license](https://creativecommons.org/licenses/by-nc-nd/4.0/legalcode),

# and code is released under the [MIT license](https://opensource.org/licenses/MIT).*

#

# < [Separating Milk](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/03.04-Separating-Milk.ipynb) | [Contents](toc.ipynb) | [Material Balances](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/04.00-Material-Balances.ipynb) > # # Adipic Acid Flowsheet

# ## Summary

#

# This [Jupyter notebook](http://ipython.org/notebook.html) demonstrates the formulation and solution of material balances for a hypothetical adipic acid process described by Murphy (2005, Example 2.15) using the [symbolic algebra package Sympy](http://sympy.org/en/index.html).

# ## Problem Statement

# [Adipic acid](http://pubchem.ncbi.nlm.nih.gov/summary/summary.cgi?cid=196) (C6H10O4) (also called hexanedioic acid) rarely occurs in nature, but approximately 2.5 billion kilograms are produced per year from petrochemical feedstocks primarily for the production of nylon.

#

#

# # Adipic Acid Flowsheet

# ## Summary

#

# This [Jupyter notebook](http://ipython.org/notebook.html) demonstrates the formulation and solution of material balances for a hypothetical adipic acid process described by Murphy (2005, Example 2.15) using the [symbolic algebra package Sympy](http://sympy.org/en/index.html).

# ## Problem Statement

# [Adipic acid](http://pubchem.ncbi.nlm.nih.gov/summary/summary.cgi?cid=196) (C6H10O4) (also called hexanedioic acid) rarely occurs in nature, but approximately 2.5 billion kilograms are produced per year from petrochemical feedstocks primarily for the production of nylon.

#

#  #

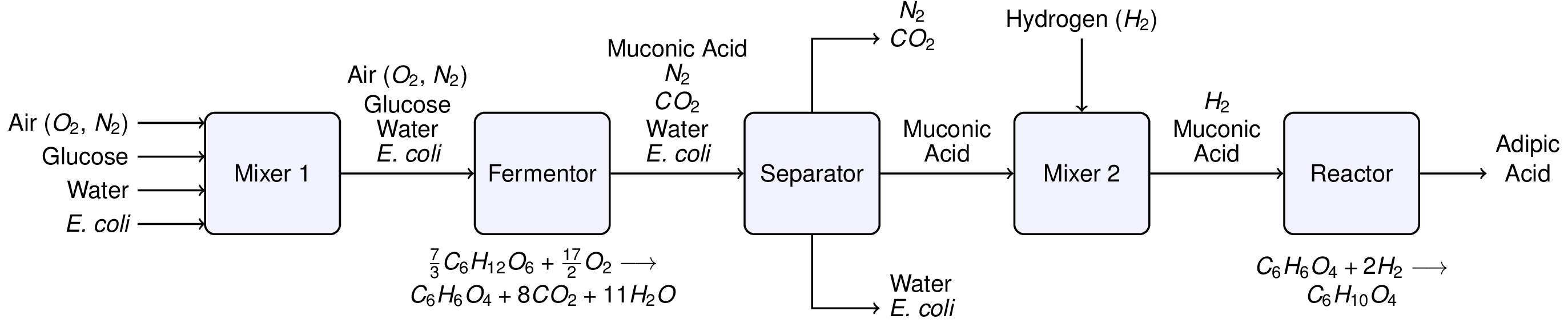

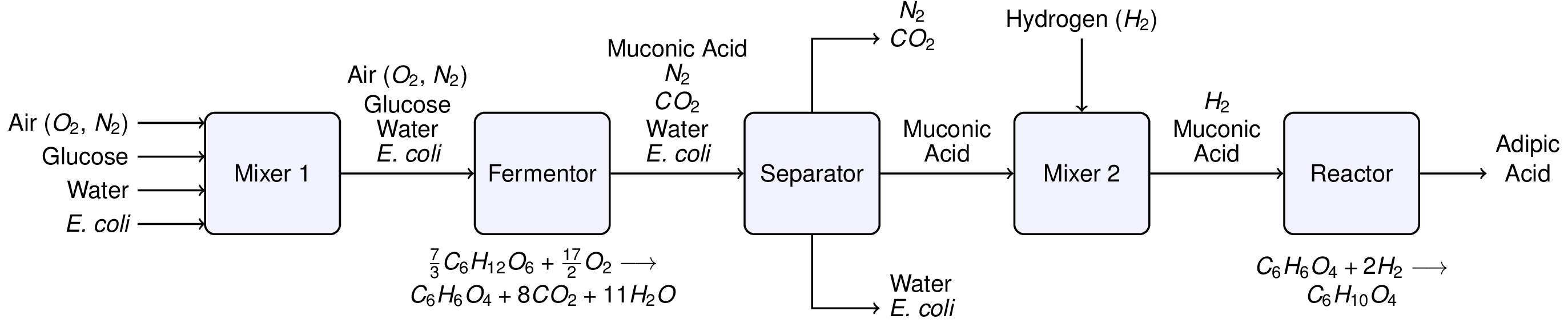

# Recently there has been interest in [producing adipic acid from renewable resources](http://www.ihs.com/products/chemical/technology/pep/bio-based-adipic-acid.aspx). [For example, starting with glucose](http://pubs.acs.org/doi/abs/10.1021/ja00080a057) (C6H12O6), muconic acid (C6H6O4) is produced through fermentation with a genetically modified e. coli. via the reaction

#

# 7⁄3 C6H12O6 + 17⁄2 O2 ➝ C6H6O4 + 8 CO2 + 11 H2O

#

# that is subsequently hydrogentated to form adipic acid

#

# C6H6O4 + 2 H2 ➝ C6H10O4

#

# Murphy (2005, Example 2.15) outlines a hypothetical flowsheet for this process:

#

#

#

# Recently there has been interest in [producing adipic acid from renewable resources](http://www.ihs.com/products/chemical/technology/pep/bio-based-adipic-acid.aspx). [For example, starting with glucose](http://pubs.acs.org/doi/abs/10.1021/ja00080a057) (C6H12O6), muconic acid (C6H6O4) is produced through fermentation with a genetically modified e. coli. via the reaction

#

# 7⁄3 C6H12O6 + 17⁄2 O2 ➝ C6H6O4 + 8 CO2 + 11 H2O

#

# that is subsequently hydrogentated to form adipic acid

#

# C6H6O4 + 2 H2 ➝ C6H10O4

#

# Murphy (2005, Example 2.15) outlines a hypothetical flowsheet for this process:

#

#  #

# Neglecting the _E. coli_, solve for the flowrates necessary to produce 12,000 kg/hour of adipic acid assuming that glucose is available as a 10 mg/mL solution.

#

# ## Solution

# ### Process Variables

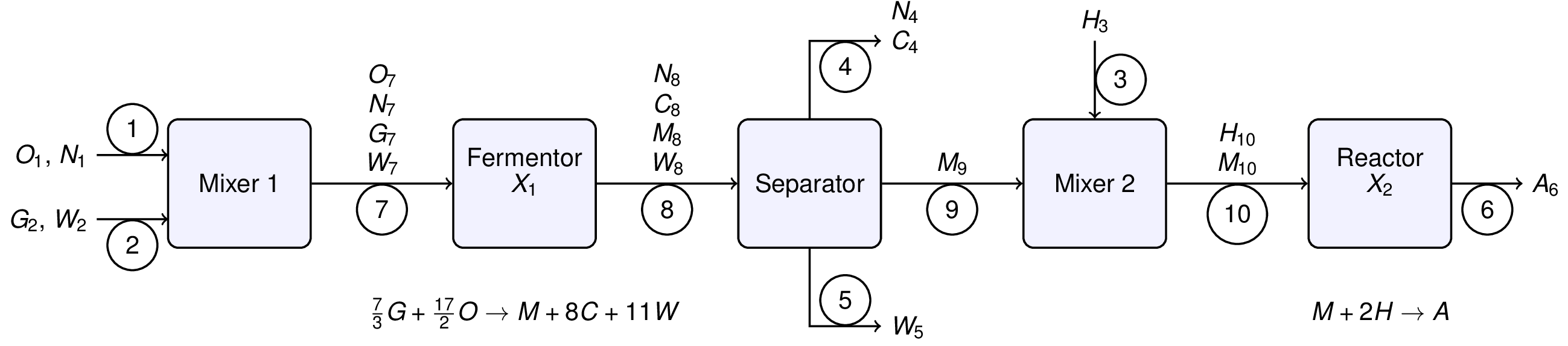

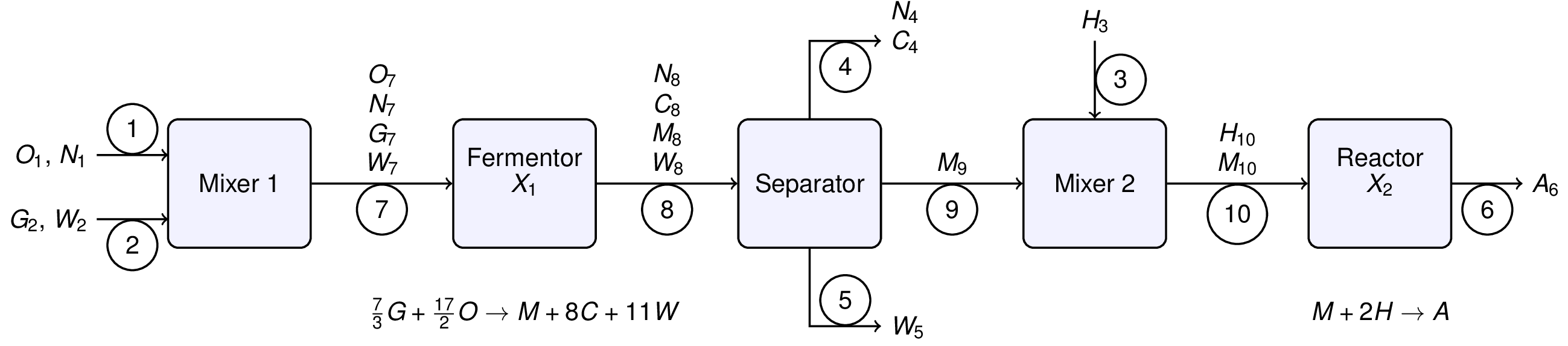

# We begin by relabeling the process flowsheet with stream numbers, stream variables, and extents of reaction. There are chemical species are abbreviated as follows:

#

# * A: adipic acid

# * C: carbon dioxide

# * G: glucose

# * H: hydrogen

# * M: muconic acid

# * N: nitrogen

# * O: oxygen

# * W: water

#

# and where X1 and X2 denote the extents of reactions 1 and 2, respectively. The stream variables denote chemical flowrates in units of kg/hour. The extents of reaction will be in units of kg-mol/hour.

#

#

#

# Neglecting the _E. coli_, solve for the flowrates necessary to produce 12,000 kg/hour of adipic acid assuming that glucose is available as a 10 mg/mL solution.

#

# ## Solution

# ### Process Variables

# We begin by relabeling the process flowsheet with stream numbers, stream variables, and extents of reaction. There are chemical species are abbreviated as follows:

#

# * A: adipic acid

# * C: carbon dioxide

# * G: glucose

# * H: hydrogen

# * M: muconic acid

# * N: nitrogen

# * O: oxygen

# * W: water

#

# and where X1 and X2 denote the extents of reactions 1 and 2, respectively. The stream variables denote chemical flowrates in units of kg/hour. The extents of reaction will be in units of kg-mol/hour.

#

#  # In[1]:

# Import the symbolic algebra package sympy

import sympy as sym

# Extents of reactions 1 and 2

sym.var('X1 X2')

# Stream variables

sym.var('O1 N1') # Stream 1

sym.var('G2 W2') # Stream 2

sym.var('H3') # Stream 3

sym.var('N4 C4') # Stream 4

sym.var('W5') # Stream 5

sym.var('A6') # Stream 6

sym.var('O7 N7 G7 W7') # Stream 7

sym.var('N8 W8 C8 M8') # Stream 8

sym.var('M9') # Stream 9

sym.var('H10 M10') # Stream 10

# Because the flowsheet includes reactions, it will be necessary to include molecular weights in the mass balance expressions. For this purpose we gather the molecular weights of all species into a python dictionary indexed by the chemical species.

# In[2]:

MW = {

'A': 146.14,

'C': 44.01,

'G': 180.16,

'H': 2.02,

'M': 142.11,

'N': 14.01,

'O': 16.00,

'W': 18.02

}

# ### Specifications

# In[3]:

specs = [

sym.Eq(A6, 12000),

sym.Eq(N1/MW['N'], (0.79/0.21)*(O1/MW['O'])),

sym.Eq(G2, 0.01*W2)

]

# ### Material Balances

# In[4]:

mixer1 = [

sym.Eq(0, O1 - O7),

sym.Eq(0, N1 - N7),

sym.Eq(0, G2 - G7),

sym.Eq(0, W2 - W7)

]

reactor1 = [

sym.Eq(0, O7 - MW['O']*(17/2)*X1),

sym.Eq(0, N7 - N8),

sym.Eq(0, G7 - MW['G']*(7/3)*X1),

sym.Eq(0, -C8 + MW['C']*8*X1),

sym.Eq(0, -M8 + MW['M']*X1),

sym.Eq(0, W7 - W8 + MW['W']*11*X1)

]

separator = [

sym.Eq(0, N8 - N4),

sym.Eq(0, C8 - C4),

sym.Eq(0, M8 - M9),

sym.Eq(0, W8 - W5)

]

mixer2 = [

sym.Eq(0, M9 - M10),

sym.Eq(0, H3 - H10)

]

reactor2 = [

sym.Eq(0, H10 - MW['H']*2*X2),

sym.Eq(0, M10 - MW['M']*X2),

sym.Eq(0, -A6 + MW['A']*X2)

]

mbals = mixer1 + reactor1 + separator + mixer2 + reactor2

# In[5]:

specs + mbals

# ### Solution

# In[6]:

soln = sym.solve(mbals + specs)

soln

# In[7]:

for key in soln.keys():

print("{:3s} {:10.1f}".format(str(key), float(soln[key])))

# In[ ]:

#

# < [Separating Milk](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/03.04-Separating-Milk.ipynb) | [Contents](toc.ipynb) | [Material Balances](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/04.00-Material-Balances.ipynb) >

# In[1]:

# Import the symbolic algebra package sympy

import sympy as sym

# Extents of reactions 1 and 2

sym.var('X1 X2')

# Stream variables

sym.var('O1 N1') # Stream 1

sym.var('G2 W2') # Stream 2

sym.var('H3') # Stream 3

sym.var('N4 C4') # Stream 4

sym.var('W5') # Stream 5

sym.var('A6') # Stream 6

sym.var('O7 N7 G7 W7') # Stream 7

sym.var('N8 W8 C8 M8') # Stream 8

sym.var('M9') # Stream 9

sym.var('H10 M10') # Stream 10

# Because the flowsheet includes reactions, it will be necessary to include molecular weights in the mass balance expressions. For this purpose we gather the molecular weights of all species into a python dictionary indexed by the chemical species.

# In[2]:

MW = {

'A': 146.14,

'C': 44.01,

'G': 180.16,

'H': 2.02,

'M': 142.11,

'N': 14.01,

'O': 16.00,

'W': 18.02

}

# ### Specifications

# In[3]:

specs = [

sym.Eq(A6, 12000),

sym.Eq(N1/MW['N'], (0.79/0.21)*(O1/MW['O'])),

sym.Eq(G2, 0.01*W2)

]

# ### Material Balances

# In[4]:

mixer1 = [

sym.Eq(0, O1 - O7),

sym.Eq(0, N1 - N7),

sym.Eq(0, G2 - G7),

sym.Eq(0, W2 - W7)

]

reactor1 = [

sym.Eq(0, O7 - MW['O']*(17/2)*X1),

sym.Eq(0, N7 - N8),

sym.Eq(0, G7 - MW['G']*(7/3)*X1),

sym.Eq(0, -C8 + MW['C']*8*X1),

sym.Eq(0, -M8 + MW['M']*X1),

sym.Eq(0, W7 - W8 + MW['W']*11*X1)

]

separator = [

sym.Eq(0, N8 - N4),

sym.Eq(0, C8 - C4),

sym.Eq(0, M8 - M9),

sym.Eq(0, W8 - W5)

]

mixer2 = [

sym.Eq(0, M9 - M10),

sym.Eq(0, H3 - H10)

]

reactor2 = [

sym.Eq(0, H10 - MW['H']*2*X2),

sym.Eq(0, M10 - MW['M']*X2),

sym.Eq(0, -A6 + MW['A']*X2)

]

mbals = mixer1 + reactor1 + separator + mixer2 + reactor2

# In[5]:

specs + mbals

# ### Solution

# In[6]:

soln = sym.solve(mbals + specs)

soln

# In[7]:

for key in soln.keys():

print("{:3s} {:10.1f}".format(str(key), float(soln[key])))

# In[ ]:

#

# < [Separating Milk](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/03.04-Separating-Milk.ipynb) | [Contents](toc.ipynb) | [Material Balances](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/04.00-Material-Balances.ipynb) >

#

# Recently there has been interest in [producing adipic acid from renewable resources](http://www.ihs.com/products/chemical/technology/pep/bio-based-adipic-acid.aspx). [For example, starting with glucose](http://pubs.acs.org/doi/abs/10.1021/ja00080a057) (C6H12O6), muconic acid (C6H6O4) is produced through fermentation with a genetically modified e. coli. via the reaction

#

# 7⁄3 C6H12O6 + 17⁄2 O2 ➝ C6H6O4 + 8 CO2 + 11 H2O

#

# that is subsequently hydrogentated to form adipic acid

#

# C6H6O4 + 2 H2 ➝ C6H10O4

#

# Murphy (2005, Example 2.15) outlines a hypothetical flowsheet for this process:

#

#

#

# Recently there has been interest in [producing adipic acid from renewable resources](http://www.ihs.com/products/chemical/technology/pep/bio-based-adipic-acid.aspx). [For example, starting with glucose](http://pubs.acs.org/doi/abs/10.1021/ja00080a057) (C6H12O6), muconic acid (C6H6O4) is produced through fermentation with a genetically modified e. coli. via the reaction

#

# 7⁄3 C6H12O6 + 17⁄2 O2 ➝ C6H6O4 + 8 CO2 + 11 H2O

#

# that is subsequently hydrogentated to form adipic acid

#

# C6H6O4 + 2 H2 ➝ C6H10O4

#

# Murphy (2005, Example 2.15) outlines a hypothetical flowsheet for this process:

#

#  #

# Neglecting the _E. coli_, solve for the flowrates necessary to produce 12,000 kg/hour of adipic acid assuming that glucose is available as a 10 mg/mL solution.

#

# ## Solution

# ### Process Variables

# We begin by relabeling the process flowsheet with stream numbers, stream variables, and extents of reaction. There are chemical species are abbreviated as follows:

#

# * A: adipic acid

# * C: carbon dioxide

# * G: glucose

# * H: hydrogen

# * M: muconic acid

# * N: nitrogen

# * O: oxygen

# * W: water

#

# and where X1 and X2 denote the extents of reactions 1 and 2, respectively. The stream variables denote chemical flowrates in units of kg/hour. The extents of reaction will be in units of kg-mol/hour.

#

#

#

# Neglecting the _E. coli_, solve for the flowrates necessary to produce 12,000 kg/hour of adipic acid assuming that glucose is available as a 10 mg/mL solution.

#

# ## Solution

# ### Process Variables

# We begin by relabeling the process flowsheet with stream numbers, stream variables, and extents of reaction. There are chemical species are abbreviated as follows:

#

# * A: adipic acid

# * C: carbon dioxide

# * G: glucose

# * H: hydrogen

# * M: muconic acid

# * N: nitrogen

# * O: oxygen

# * W: water

#

# and where X1 and X2 denote the extents of reactions 1 and 2, respectively. The stream variables denote chemical flowrates in units of kg/hour. The extents of reaction will be in units of kg-mol/hour.

#

#  # In[1]:

# Import the symbolic algebra package sympy

import sympy as sym

# Extents of reactions 1 and 2

sym.var('X1 X2')

# Stream variables

sym.var('O1 N1') # Stream 1

sym.var('G2 W2') # Stream 2

sym.var('H3') # Stream 3

sym.var('N4 C4') # Stream 4

sym.var('W5') # Stream 5

sym.var('A6') # Stream 6

sym.var('O7 N7 G7 W7') # Stream 7

sym.var('N8 W8 C8 M8') # Stream 8

sym.var('M9') # Stream 9

sym.var('H10 M10') # Stream 10

# Because the flowsheet includes reactions, it will be necessary to include molecular weights in the mass balance expressions. For this purpose we gather the molecular weights of all species into a python dictionary indexed by the chemical species.

# In[2]:

MW = {

'A': 146.14,

'C': 44.01,

'G': 180.16,

'H': 2.02,

'M': 142.11,

'N': 14.01,

'O': 16.00,

'W': 18.02

}

# ### Specifications

# In[3]:

specs = [

sym.Eq(A6, 12000),

sym.Eq(N1/MW['N'], (0.79/0.21)*(O1/MW['O'])),

sym.Eq(G2, 0.01*W2)

]

# ### Material Balances

# In[4]:

mixer1 = [

sym.Eq(0, O1 - O7),

sym.Eq(0, N1 - N7),

sym.Eq(0, G2 - G7),

sym.Eq(0, W2 - W7)

]

reactor1 = [

sym.Eq(0, O7 - MW['O']*(17/2)*X1),

sym.Eq(0, N7 - N8),

sym.Eq(0, G7 - MW['G']*(7/3)*X1),

sym.Eq(0, -C8 + MW['C']*8*X1),

sym.Eq(0, -M8 + MW['M']*X1),

sym.Eq(0, W7 - W8 + MW['W']*11*X1)

]

separator = [

sym.Eq(0, N8 - N4),

sym.Eq(0, C8 - C4),

sym.Eq(0, M8 - M9),

sym.Eq(0, W8 - W5)

]

mixer2 = [

sym.Eq(0, M9 - M10),

sym.Eq(0, H3 - H10)

]

reactor2 = [

sym.Eq(0, H10 - MW['H']*2*X2),

sym.Eq(0, M10 - MW['M']*X2),

sym.Eq(0, -A6 + MW['A']*X2)

]

mbals = mixer1 + reactor1 + separator + mixer2 + reactor2

# In[5]:

specs + mbals

# ### Solution

# In[6]:

soln = sym.solve(mbals + specs)

soln

# In[7]:

for key in soln.keys():

print("{:3s} {:10.1f}".format(str(key), float(soln[key])))

# In[ ]:

#

# < [Separating Milk](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/03.04-Separating-Milk.ipynb) | [Contents](toc.ipynb) | [Material Balances](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/04.00-Material-Balances.ipynb) >

# In[1]:

# Import the symbolic algebra package sympy

import sympy as sym

# Extents of reactions 1 and 2

sym.var('X1 X2')

# Stream variables

sym.var('O1 N1') # Stream 1

sym.var('G2 W2') # Stream 2

sym.var('H3') # Stream 3

sym.var('N4 C4') # Stream 4

sym.var('W5') # Stream 5

sym.var('A6') # Stream 6

sym.var('O7 N7 G7 W7') # Stream 7

sym.var('N8 W8 C8 M8') # Stream 8

sym.var('M9') # Stream 9

sym.var('H10 M10') # Stream 10

# Because the flowsheet includes reactions, it will be necessary to include molecular weights in the mass balance expressions. For this purpose we gather the molecular weights of all species into a python dictionary indexed by the chemical species.

# In[2]:

MW = {

'A': 146.14,

'C': 44.01,

'G': 180.16,

'H': 2.02,

'M': 142.11,

'N': 14.01,

'O': 16.00,

'W': 18.02

}

# ### Specifications

# In[3]:

specs = [

sym.Eq(A6, 12000),

sym.Eq(N1/MW['N'], (0.79/0.21)*(O1/MW['O'])),

sym.Eq(G2, 0.01*W2)

]

# ### Material Balances

# In[4]:

mixer1 = [

sym.Eq(0, O1 - O7),

sym.Eq(0, N1 - N7),

sym.Eq(0, G2 - G7),

sym.Eq(0, W2 - W7)

]

reactor1 = [

sym.Eq(0, O7 - MW['O']*(17/2)*X1),

sym.Eq(0, N7 - N8),

sym.Eq(0, G7 - MW['G']*(7/3)*X1),

sym.Eq(0, -C8 + MW['C']*8*X1),

sym.Eq(0, -M8 + MW['M']*X1),

sym.Eq(0, W7 - W8 + MW['W']*11*X1)

]

separator = [

sym.Eq(0, N8 - N4),

sym.Eq(0, C8 - C4),

sym.Eq(0, M8 - M9),

sym.Eq(0, W8 - W5)

]

mixer2 = [

sym.Eq(0, M9 - M10),

sym.Eq(0, H3 - H10)

]

reactor2 = [

sym.Eq(0, H10 - MW['H']*2*X2),

sym.Eq(0, M10 - MW['M']*X2),

sym.Eq(0, -A6 + MW['A']*X2)

]

mbals = mixer1 + reactor1 + separator + mixer2 + reactor2

# In[5]:

specs + mbals

# ### Solution

# In[6]:

soln = sym.solve(mbals + specs)

soln

# In[7]:

for key in soln.keys():

print("{:3s} {:10.1f}".format(str(key), float(soln[key])))

# In[ ]:

#

# < [Separating Milk](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/03.04-Separating-Milk.ipynb) | [Contents](toc.ipynb) | [Material Balances](http://nbviewer.jupyter.org/github/jckantor/CBE20255/blob/master/notebooks/04.00-Material-Balances.ipynb) >